Why CheckWave® ?

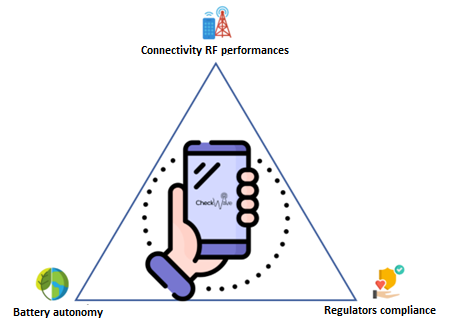

The wireless ecosystem has entered a new era. More connected devices—new, reused, or professionally reintroduced into the market—mean exponential growth in RF testing needs, higher user expectations, and stricter operational demands on connectivity, energy efficiency, and regulatory compliance.

Consumers and professionals increasingly expect proof that devices are not only connected, but well calibrated, energy-efficient, and compliant at the unit level.

At the same time, the hardware reality is complex. High production volumes, partially manual assembly processes, ultra-tight cost constraints, and multi-sourced electronic components introduce natural unit-to-unit variability, even within identical device models.

This variability directly impacts real-world radio behavior.

That is why RF performance is coming /to the forefront—not as a technical detail, but as a key indicator of device quality at scale.

RF Performance vs Connectivity

RF performance is the engine. Connectivity is the ride.

Connectivity is the experience: network bars, download speed, call stability.

RF performance is the foundation that makes it possible: antenna tuning, signal efficiency, power behavior, sensitivity, and electromagnetic balance.

A device can look connected and still:

- consume too much energy,

- overheat under network load,

- emit more RF power than needed,

- deliver unstable performance in mobility,

- drift close to SAR regulatory limits.

True wireless quality is not only being connected—it is how efficiently, reliably, and sustainably the connection is delivered.

CheckWave® supports the industry to implement this new process in production. This allows consumers to have the information that their smartphones and connected devices have been tested.

Why RF Performance Directly Impacts Battery Life ?

Battery autonomy is not only defined by battery capacity

it is equally defined by how efficiently the device communicates with the network.

When the RF system is not optimally calibrated or detuned, the device must compensate by:

- Increasing transmission power to maintain network link → higher energy draw

- Extending radio activity time because data exchange becomes less efficient

- Repeating signal attempts due to packet loss or instability

- Operating RF amplifiers outside optimal efficiency zones, wasting energy as

- Triggering more network scanning and re-selection cycles

This results in:

Faster battery drain

Higher device temperature

Less stable connectivity in low-coverage areas

Lower real autonomy compared to the device’s technical capacity

A well-tuned RF system doesn’t only perform better—it consumes significantly less energy to do the same job.

CheckWave®- 3 Key requirements

CheckWave® is a program that meets similar characteristics to ISO and is structured to be assessed by an authorized party. Like ISO standards, it covers the fundamental quality control points, including human resources skills and the quality management process, such as the specific industrial EMF* process in factories and production lines, key technological aspects with the definition of tests, and industrial traceability.

Disruptive industrial innovation program for electromagnetic waves testing

Human resources competencies and process management

Specific industrial process, key technological aspects & tests definition

Traceability

*ElectroMagnetic Field

The Industrial Reality: Volume, Variability, Performance

Delivering millions of wireless devices is an outstanding industrial achievement, balancing:

-

-

- Extreme cost efficiency,

- Fast production cycles,

- Multiple component supply chains,

- Continuous hardware revisions.

To meet these constraints, manufacturing and refurbishment operations integrate parts from multiple suppliers, adapt assembly processes, and rely on manual operations where full automation is not feasible.

These are not shortcomings—they are structural realities of highly competitive hardware ecosystems.

Yet, they naturally introduce device-level variability, especially in the radio chain.

As connectivity complexity increases (5G, multi-antenna systems, dynamic spectrum), the impact of RF variability becomes even more visible on:

-

- Network performance

- Energy consumption

- Thermal behavior

- SAR consistency

- Overall product quality perception

-

RF Testing Must Now Evolve from Spot-Check to Systematic Intelligence

Historically, RF validation focused on:

- Prototypes

- Pre-production samples

- Periodic sample testing

This approach remains essential, but it no longer reflects real performance dispersion at scale.

Across the device market—new, renewed, or reintroduced into circulation—RF quality assurance must now expand to support:

- Higher test volumes

- Faster execution

- Unit-level insight

- Energy efficiency verification

- SAR compliance confidence

- Industrial process integration without bottlenecks

This is where CheckWave® delivers a new standard.

CheckWave®: A Scalable RF Quality Assurance Framework

CheckWave® enables fast, precise, and industrial-grade RF assessment, validating connectivity efficiency, power behavior, SAR stability, and overall radio quality—at any scale.

CheckWave® adapts to different needs through progressive deployment models:

| Level | Purpose | Typical Scope | Core Value |

| CheckWave® Pioneer | Innovate • Benchmark • Validate early |

R&D, prototypes, early hardware iterations | Detect RF bottlenecks, optimize design choices |

| CheckWave® Select |

Sample |

Periodic batches, quality gates, fleet profiling | Monitor drift, validate consistency, prevent anomalies |

| CheckWave® Elite | Measure 100% • Validate every unit |

Production lines, refurbishment operations, high-assurance programs | Guarantee RF efficiency, battery performance, connectivity, and SAR compliance per device |

These levels are not rigid labels, but scalable reference architectures that adapt to operational maturity and throughput requirements.

Why This Matters Across Wireless Device Ecosystems

Whether devices are newly built, reintroduced after refurbishment, or embedded into IoT fleets, the expectations are converging:

- Connectivity must be reliable

- Energy consumption must be optimized

- Performance must be consistent device to device

- SAR compliance must be stable, measurable and proven

- Testing must be fast, scalable, operator-independent and industrially viable

CheckWave® was created to answer all these requirements—with one philosophy:

Test smarter. Scale better. Deliver trust at unit level.

CheckWave® “first successes”

“For more than 30 years, the Itancia group has firmly defended 3 essential pillars: ecology, energy transition and the health of its users. Pioneer in the reconditioning of technological products, through our activity, we are proud to have developed a unique industrial tool that allows us to measure the SAR value of smartphones directly on our reconditioning line. The CheckWave® label, a major technological initiative, certifies the quality of our work and highlights our historical know-how on the refurbished technological products market. The market, the users and the companies have from now on an obvious answer to their needs of transparency, quality and safety.”

![]()